EV drivetrains and particularly batteries are developing at a remarkable pace compared with the combustion engine.

As a result, range has increased but probably even more marked is the desire to bring charging times in line with ICE refuelling.

BYD recently announced its Super e-Platform along with the latest ‘flash-charge’ version of its lithium-iron-phosphate (LFP) Blade battery, which is promised to get close to ICE refuelling times by recharging in six minutes.

The new platform is claimed to support charging at up to 1000kW, which seems incredible given the typical rapid-charge rate was 50kW just a few years ago.

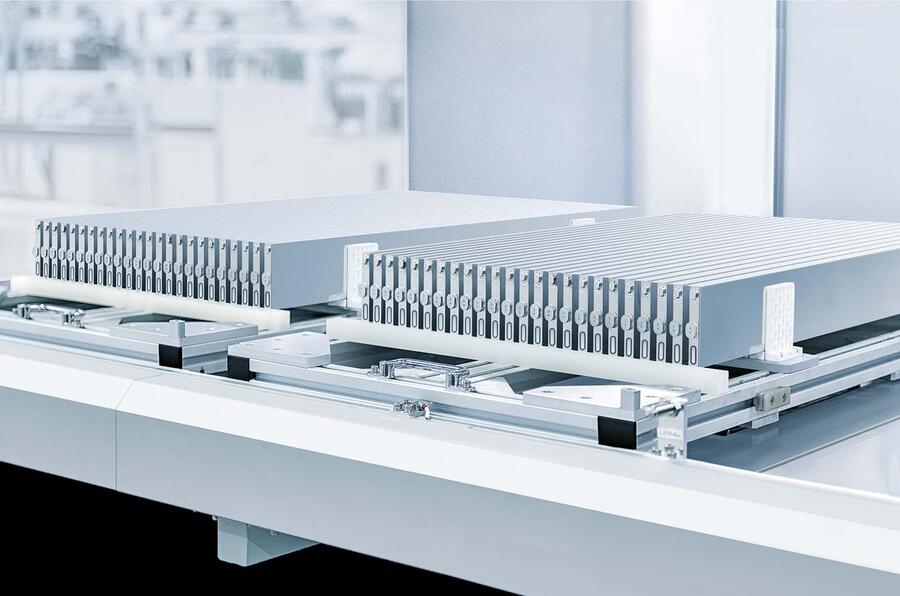

The name Blade describes the unusual design of the battery, where long, slim cells almost a metre in length make up the pack, rather than modules packed full of smaller pouch, cylindrical or prism cells.

In that sense it’s unusual, but its LFP chemistry isn’t. The advantage of LFP lies in being economical, cobalt- and nickel-free and, above all, safer. LFP battery chemistry is often used in stationary battery systems (including domestic solar systems) and releases heat slowly and doesn’t release oxygen if damaged.

BYD has demonstrated that its Blade battery cell passes the nail penetration test without emitting fire or smoke, whereas a cell based on alternative chemistry like NMC (lithium, nickel, manganese, cobalt oxide) subjected to the same test reacts violently.

While the basic chemistry of the LFP battery isn’t extraordinary, achieving a charge rate of 10C for the BYD flash-charge battery is. The ‘C’ rate is the rate at which a battery charges relative to its capacity and illustrates how quickly a battery can accept and discharge energy.

A battery charging from 0% to 100% capacity in one hour is charging at 1C but at 10C that would drop to six minutes. For an electric car in the real world, that would depend on a charger being able to deliver enough power and other factors such as how effectively the temperature of the battery is managed.

To achieve that, the Super e-Platform has a 1000V architecture that includes not just the battery but also the motor, power supply and air conditioning. Four thousand 1MW (1000kW) chargers are already planned for China so that just leaves the question of how an LFP battery can accept charge more quickly than any other battery tech.

When charging, lithium ions travel from the positive electrode (cathode) to the negative electrode (anode) in each cell. BYD says to achieve the colossal charge rate it “built ultra-fast ion channels, reducing the battery’s internal resistance by 50%”.

Join the debate

Add your comment

Yes, in a similar fashion to max'ing out the revs on an ICE with every gear change. In the last 2 years I would never have needed to use such a rapid overpriced charger, let alone charge the battery to 100%.

Just how many days does a 70kwh battery, normal resistance, take to go flat sitting on your drive?

Here's hoping this battery does succeed in giving parity with ICE refuelling,ok, infrastructure will take time to catch-up,but, this would definitely get me into an EV if you can charge up like an ICE car, you know, drive into the charge station plug in ,fill up,pay then go in about ten minutes or so.

No mention of how much such rapid charging, may affect the overall lifespan of the batteries.

BYD offer an 8 year 125,000 mile warranty on the traction battery of their EVs.

Never seen a mention of the effect on an ICE if you max out the revs before every gear change either.